DOD Industrial Prints & Marking are the leading choice for printing and coding on industrial products. Designed for challenging applications like printing on metal, plastic, and rubber, INK JET large and small character inkjet coders offer excellent printing performance and low maintenance for maximum production uptime.

Rugged design inkjet printers stand out as the preferred choice for printing and coding on industrial products, demonstrating exceptional versatility in challenging applications, including printing on metal, plastic, and rubber. Both large and small character inkjet coders are available, offering outstanding printing performance and requiring low maintenance to ensure maximum production uptime.

DOD Industrial Prints & Marking

Maximize Uptime with DOD's High-Performance Inkjet Coders

The large character inkjet printing system

DOD 2.0 prints texts, data and logos with a print height of up to 140 mm per print head. The resolution meets the coding and marking requirements for a vast range of industrial applications

The robust inkjet printer is easy to handle and highly flexible due to the modular design of the system com- ponents. The print heads feature 7, 16 or 32 nozzles and can be combined into one printing system – up to 16 print heads per device.

Areas of application

- Absorbent and non-absorbent surfaces such as paper, cardboard, metal, glass, ceramic, stone, wood, plastic, rubber, foils, carpet, textiles, fleece, organic surfaces etc.

- Under extreme environmental conditions such as dust, moisture, vibration and temperature fluctuations

Print head variants

- 7 nozzles: single-line marking with a height of 5 to 27 mm

- 16 nozzles: single- to two-line markings with a height of 5 to 67 mm

- 32 nozzles: single- to five-line markings with a height of 5 to 140 mm

Advantages:

- Potential speeds of up to 600 m/min

- Print heads with cascading capability for printing large surfaces: up to 512 nozzles can be addressed

- Economical use of consumables

- Suitable for pigmented and non-pigmented inks

- Protection class IP65

- High level of system availability and process reliability thanks to fast changeover system for modular components

- Fast cleaning of the print head at the touch of a button

- Dot size control, freely adjust- able drop size for economical use of consumables

- Modern interface connection to higher-level software systems for improving efficiency and reli- ability of production

- Fine adjustment of height and width ratio of the text to optimize the print image

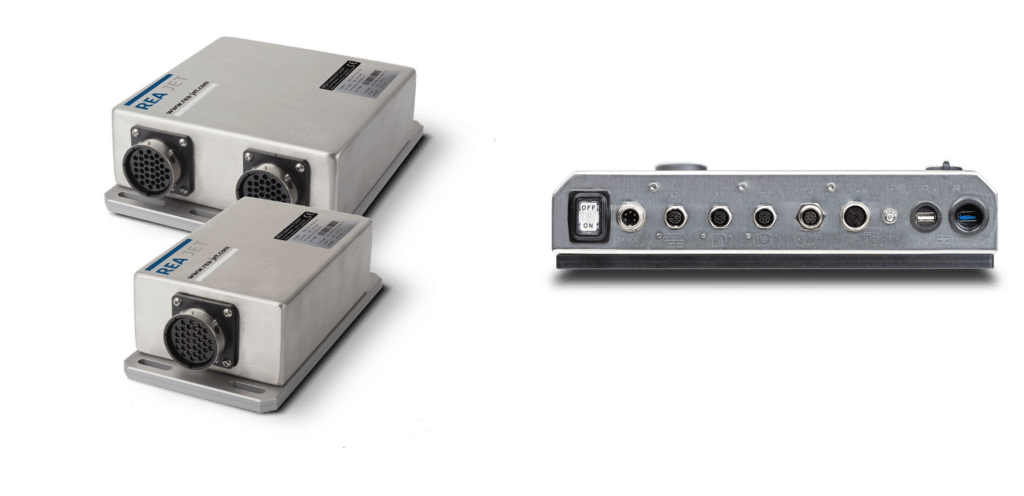

DOD 2.0 – Control Center

- Sturdy and high-quality stainlesssteel casing desi- gned for daily work in harsh and rugged industrial environments

- Protection Class IP65: dust-proof and splash water protected for toughest industrial use when required

- 24 V power supply: for direct integration into machines and systems

- Consistent graphical user interface WYSIWYG: realistic display of print contents

- Support of all True Type Fonts (TTFs): maximum design flexibility for your print texts

- Operation: number pad, cursor block, function keys, dial with push button function

Designed for Global Compatibility

Get connected

- Wide range power supply available: for immediate global use

- Full Unicode support: all global languages can be printed for companies with international customers

- XML-based data structure and communication protocol: globally standard for data compatibility

- Integrated VNC-Server: Remote maintenance tool for diagnosis and support

- Uniform communication protocol for condition monitoring across multiple devices: allowing user-specific signal processing

- Integrated webserver: enables print system operation via PC, tablets or smartphone

- ■ Power supply: 24 V DC from SELV-Power Supply

- ■ External power adaptor IP67 (100 V – 277 V AC, 50-60 Hz)

- ■ Ethernet interface 100 Mbit/s M12-D-coded for fast data exchange

- ■ Serial interfaces RS232/422

- ■ USB interface

- ■ Digital I/O interface: freely programmable

- ■ 2 print head connection strings: up to 512 nozzles selectable

- ■ Product sensor and shaft encoder port

Industrial Ink and Primer Supply Units

VANS MARK offers various ink and primer supplies – the right solution for every customer requirement.

- ■ Highest chemical resistance

- ■ Best mixing performance for inks and primers

- ■ Avoidance of sedimentation

- ■ Greater range through higher filling capacity

- ■ Automatic flushing system

- ■ Automatic or manual operation

- ■ Comprehensive accessories

- ■ Over 500 inks and primers

The Single Operating Concept for all REA JET Technologies

Touch Screen

Touch screen for operation directly at the production line

Glove Operation

Central push-turn jog-dial knob even for glove operation directly at the production line

WLAN Browser Operation

Browser operation through mobile devices (PC, tablet, smartphone) via WLAN / WebGui

PC Operation

Remote control from desktop computer or control stand

Remote Maintenance

Remote maintenance and control available via VNC server

Keyboard Entry

For regularly recurrent extensive text input at the production line – use of international USB keyboards possible