Unlike most consumer products, which usually leave the factory nicely branded and looking slick, the look & feel of many industrial products leaves a lot to be desired. In a way, that is a missed opportunity, as industrial customers too are not immune to a product’s appearance. Moreover, applying a label or other marking is an excellent opportunity to add all kinds of relevant product and production data. This is how it works.

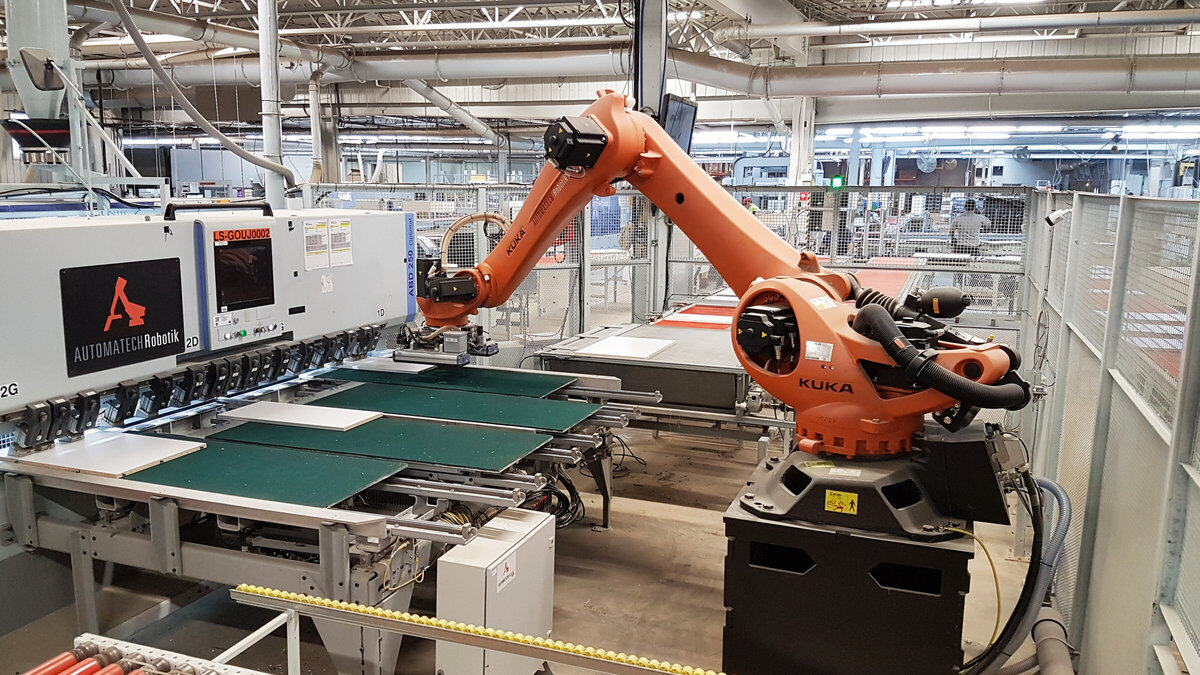

An Industrial Robotic Marking and Tagging Solutions is an autonomous system of sensors, controllers, and actuators that executes specific functions and operations in a manufacturing or processing line. They operate continuously through repetitive movement cycles as instructed by a set of commands called a program. These machines minimize or eliminate the human factor to gain various advantages in processing speed, capacity, and quality.

Traditional industrial robots must not be confused with a newer robotic technology called collaborative robots. Collaborative robots, or cobots, are designed to work simultaneously and closely with a human operator. They are much smaller but are more versatile. They are equipped with sophisticated sensors that allow them to perceive the actions of nearby personnel.